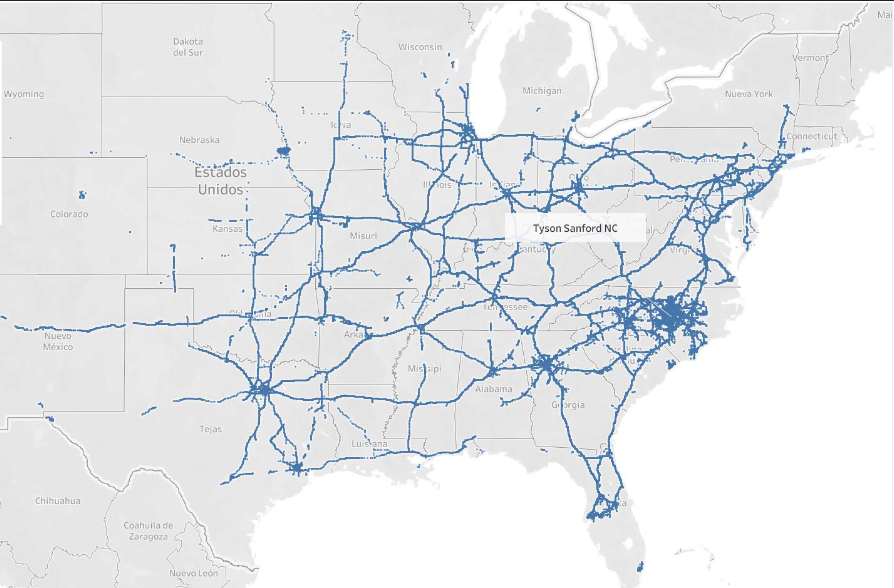

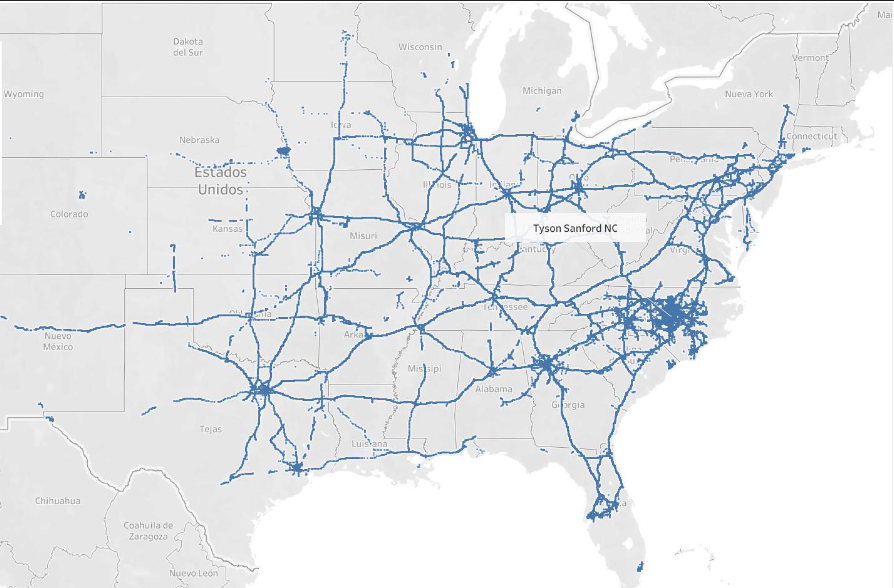

Location intelligence through spatial data allows leaders to create a detailed supply chain mapping and thereby identify opportunities and mitigate distribution risks for any company.

Supply chain mapping through spatial data and Big Data techniques allows leaders to implement strategies to react promptly when a supplier faces a shortage, a loss of goods, a surge in demand, or something unexpected happens. It also develops a deeper understanding of costs, lead times, and surrounding risks, thereby gaining an advantage over competitors who lack this important knowledge.

Also Read: “Geospatial Data to Optimize Supply Chains“

The application of geospatial data is used as a tool for mapping manufacturing products, processing units, supplier locations, distribution centers, and vehicle routes, etc., identifying the constraints of a geographically distributed supply chain, developing better contingency plans, anticipating and balancing supply and demand while managing risks.

These tools are vital to supply chain professionals as they manage massive amounts of location-based data to produce information that helps them to make better decisions.

Why is it so important?

The main reason is that it helps identify if there are any distribution shortages, closures, or bottlenecks that are disrupting the movement and distribution of products to stores. At the same time, it predicts problems before they occur and cause disruptions that can be harmful to the entire supply chain.

You might be interested in: “Global Supply Chain Crisis? ”

What are the benefits?

- You gain greater supply chain visibility by showing buyers, suppliers and identifying where they are located.

- Keeps risk to a minimum by drastically reducing the risk of financial damage.

- Detects potential threats on distribution routes located in regions with an above-average risk of assault, flooding, earthquakes or other natural disasters.

- Helps buyers to stay ahead of their industry, gaining a competitive advantage over rivals while reducing their level of risk.

- Designs a superior service supply chain network that minimizes inventory, labor and transportation costs without sacrificing customer satisfaction.

- Improves on-time performance by providing the critical information needed to proactively identify and correct system bottlenecks.

- Enable compliance with service level agreements by determining total costs, including transportation, labor and infrastructure investments.

- Quickly identify alternative delivery routes, reroute shipments, estimate the impact of a facility closure, etc.

At PREDIK Data-Driven we help companies to increase visibility in the supply chain, by identifying not only the first tier of suppliers in the value chain, but also 2nd, 3rd tier suppliers, and more.