The benefits of proper Big Data analytics are detecting fraud, improving productivity, reducing business operations costs, and improving decision-making. In addition, many market companies compete for the quality and quantity of their products.

Big Data has become increasingly crucial in supply chain management, providing businesses with valuable insights into their operations. From predicting demand to optimizing inventory management, all the way to enhancing delivery efficiency.

In this article we will cover the following topics:

What is supply chain management?

Supply Chain Management (SCM) consists of coordinating and managing activities involved in producing and delivering products and services, from raw materials to the final customer. It integrates processes, functions, and stakeholders to optimize the supply chain’s flow of goods, information, and finances.

SCM also includes inventory management, transportation management, and demand planning.

As IBM explains, supply chain management aims to create a competitive advantage for a business by streamlining its supply chain processes, reducing costs, increasing customer satisfaction, and improving overall responsiveness.

This means that SCM can help businesses to improve their efficiency, reduce waste, and improve their ability to respond to changing market conditions.

“SCM refers to the oversight of materials, information, and finances as they move from supplier to manufacturer to wholesaler to retailer to consumer.”

TechTarget

Overall, SCM is about managing the entire supply chain to optimize performance, reduce costs, and improve customer satisfaction. It involves various activities and stakeholders and requires coordination and integration of processes and information throughout the supply chain.

Related content: What is Supply Chain Visibility, and Why is It Important?

How can Big Data transform supply chain management?

Big data is transforming supply chain management by providing insights that enable better decision-making and optimization of operations.

With the increasing availability of data and technological advancements, supply chain managers can leverage Big Data to gain a competitive advantage in the marketplace.

Big data analytics can help supply chain managers to “optimize inventory levels, improve forecasting accuracy, reduce lead times, improve supplier performance, and enhance overall supply chain visibility” Supply Chain Digital.

Using Big data Supply Chain Managers can:

- Improve demand forecasting

- Optimize production planning and scheduling

- Increase transportation efficiency

- Reduce supply chain risks.

These benefits can be achieved through advanced analytics tools that can process vast amounts of data from multiple sources, such as sensors, social media, and transactional data.

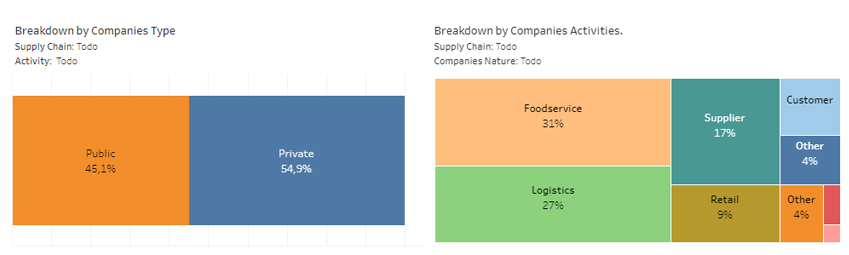

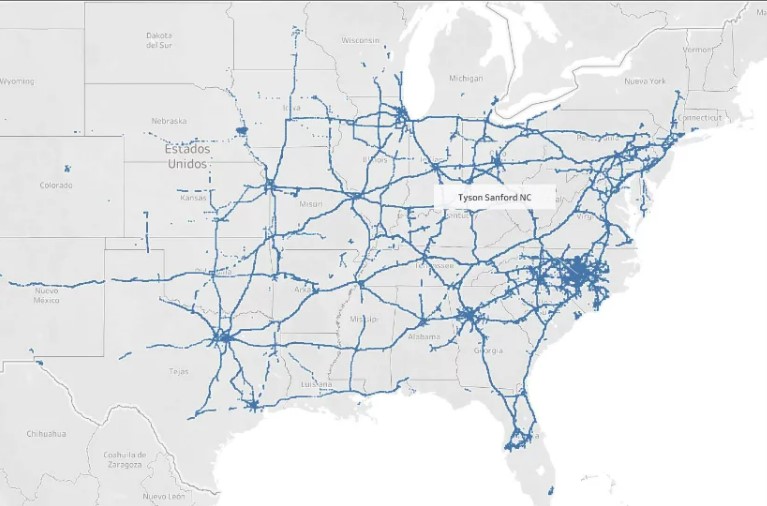

At PREDIK Data-Driven, we have develop specialized tools for Supply Chain Management. Lear more in our article: Supply chain mapping tools: How can companies benefit from them?

Real-time inventory tracking and management

Big data helps companies track inventory levels in real-time. This reduces the risk of stockouts and overstocking.

By analyzing data from sensors, RFID tags, and other sources, companies can gain insights into their inventory levels and make data-driven decisions about when and where to replenish stock.

Customer Analysis

For instance, companies can use data analytics to understand customer behavior and preferences. Then, adjust their production and inventory levels accordingly.

Predictive maintenance and quality control

Big data analytics can help companies identify potential equipment failures and quality issues before they occur.

Companies can detect patterns and anomalies by gathering sensor data and other sources. All the collected insights can indicate to supervisors any impending problems that need corrective action before they cause downtime or product defects.

In addition, Litcom highlights that Big Data can help Supply Chain Managers improve product quality, reduce waste, and identify potential supply chain disruptions before they occur.

Demand forecasting and optimization

Big data can help companies predict demand more accurately. Data analysis allows continuous production and distribution optimizations.

On the other hand, by compelling historical data with external factors, such as weather and economic conditions, companies can forecast demand more precisely and adjust their operations accordingly.

Keep control of every aspect inside your Supply Chain: See our Supply Chain Mapping Tool in Action

Supplier management and risk mitigation

Big data can help companies manage suppliers more effectively and mitigate supply chain risks.

Companies can identify potential issues before they become problems and take corrective action by using information about supplier performance. Also, companies can locate alternative suppliers in case of disruptions to their primary supply chain.

Transportation and logistics improvement

Nowadays, transportation and logistics areas rely heavily on data. Companies can optimize their networks by analyzing shipping routes, transportation modes, and delivery performance.

By using predictive analytics, decision-makers can find new ways to reduce costs while improving the company’s response times and customer satisfaction.

Want to learn more about Predictive Analytics? You can read our full guide with examples

The path to sustainability

Big data can also enable greater sustainability throughout supply chain management. Data analysis can reduce unnecessary waste, optimize transportation routes, and improve energy efficiency.

Better competitive intelligence can help companies meet their environmental and social responsibility goals while reducing costs and enhancing customer satisfaction.

The importance of having the right data

It is crucial to emphasize data quality and integration for effective supply chain management.

“The key to unlocking the value of big data in supply chain management is to have the right data, in the right format, at the right time.”

Companies require collaboration between stakeholders, suppliers, manufacturers, distributors, and retailers to ensure data consistency and accuracy.

Real Case Studies of Big Data in Supply Chain Management

How Amazon uses Big Data to improve its supply chain operations

Amazon uses different Big Data solutions to improve its supply chain operations.

One of them is through real-time data analytics to optimize inventory management. They can predict product demand and adjust inventory levels by analyzing their sales, inventory, and delivery systems.

This strategy helps prevent stockouts and reduce excess inventory, saving the company millions of dollars in storage costs.

Amazon also uses Predictive Analytics and Machine Learning to optimize its delivery network. Managers can determine the fastest and most efficient delivery routes by collecting data on weather, traffic, and shipping routes.

Learn everything about Machine Learning: Here is our complete guide

This is how Amazon always ensures that packages are delivered on time and reduces shipping costs for the company.

Also, Amazon uses customer data to improve its service. By collecting data on customer preferences, shopping habits, and feedback, they can personalize individual shopping experiences.

How Procter & Gamble collaborates with suppliers to share data and improve efficiency

Procter & Gamble collaborates with its suppliers to share data to increase efficiency. According to an IndustryWeek article, P&G utilizes technology to share data with its suppliers to improve the accuracy of forecasts and reduce inventory levels.

P&G has also created a Supplier Environmental Sustainability Scorecard to help suppliers measure and improve their environmental impact.

In addition, they have implemented a Connect + Develop program, which allows the company to work with external partners to drive innovation.

Their new program helps the company to collaborate with suppliers, universities, and start-ups to co-create new products and improve existing ones.

P&G also works with its suppliers to create value and sustainable growth. Supply chain managers work closely with their suppliers to develop sustainable solutions for products and packaging, reduce greenhouse gas emissions, and improve supply chain visibility.

How UPS’s use of data analytics to optimize its delivery routes

UPS uses data analytics to optimize its delivery routes by collecting data from various sources such as package destinations, package weights, and even weather patterns.

The collected data is then analyzed to create the most efficient delivery routes, saving the company time and money.

UPS uses a combination of GPS tracking, handheld devices, and sensors to gather data on their deliveries. Then, they create detailed maps showing the best routes (Which update in real-time based on changing conditions).

The company also implemented a package flow technology called “ORION” (On-Road Integrated Optimization and Navigation). ORION uses algorithms to analyze package delivery route data and driver movements.

This technology has reduced the number of miles driven, saving time and fuel costs. UPS reports that ORION saved the company over 39 million miles and reduced CO2 emissions by 20,000 metric tons.

So, what to expect from Big Data?

The impact of Big Data on Supply Chain Management is undeniable. With the ability to collect and analyze vast amounts of information, companies can make better-informed decisions that result in increased efficiency, reduced costs, and improved customer satisfaction.

Big data also enables predictive analytics, which allows companies to anticipate and mitigate potential disruptions in the supply chain before they occur.

While some challenges are associated with implementing data analytics throughout the Supply Chain (Such as quality and privacy concerns), the benefits far outweigh the costs.