The current global crisis in supply chains is forcing companies to manage their distribution methods by adopting a proactive approach based on Big Data and advanced analytics.

Most supply chain delays do not occur when goods are in motion between suppliers and locations. Instead, delays typically occur in handoffs between organizations and suppliers

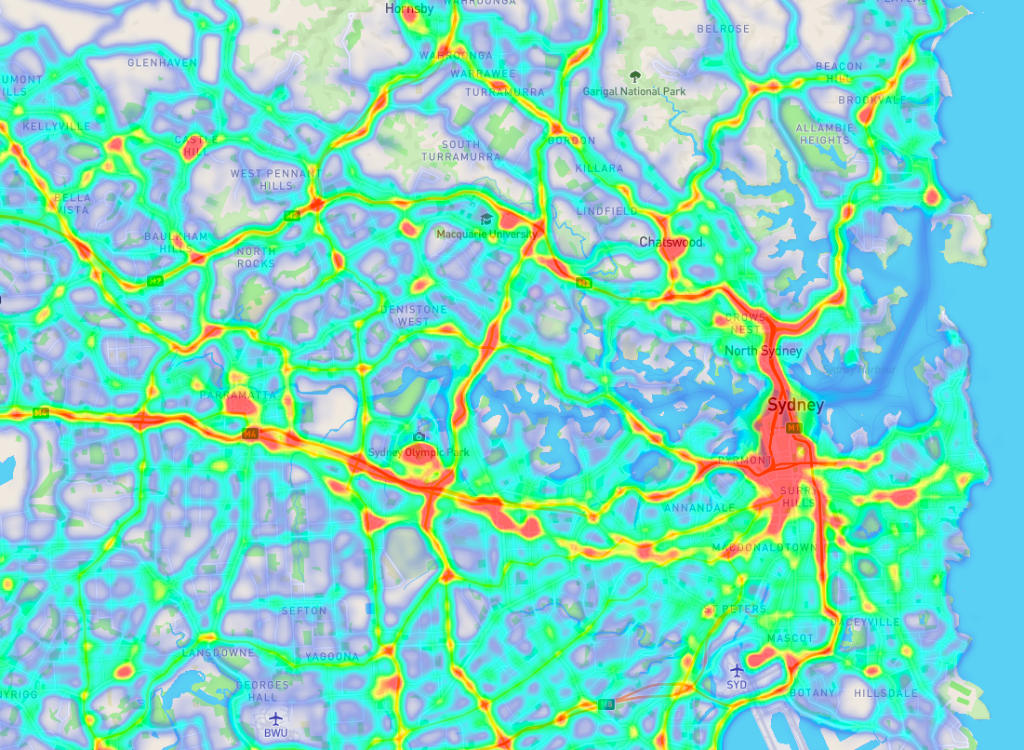

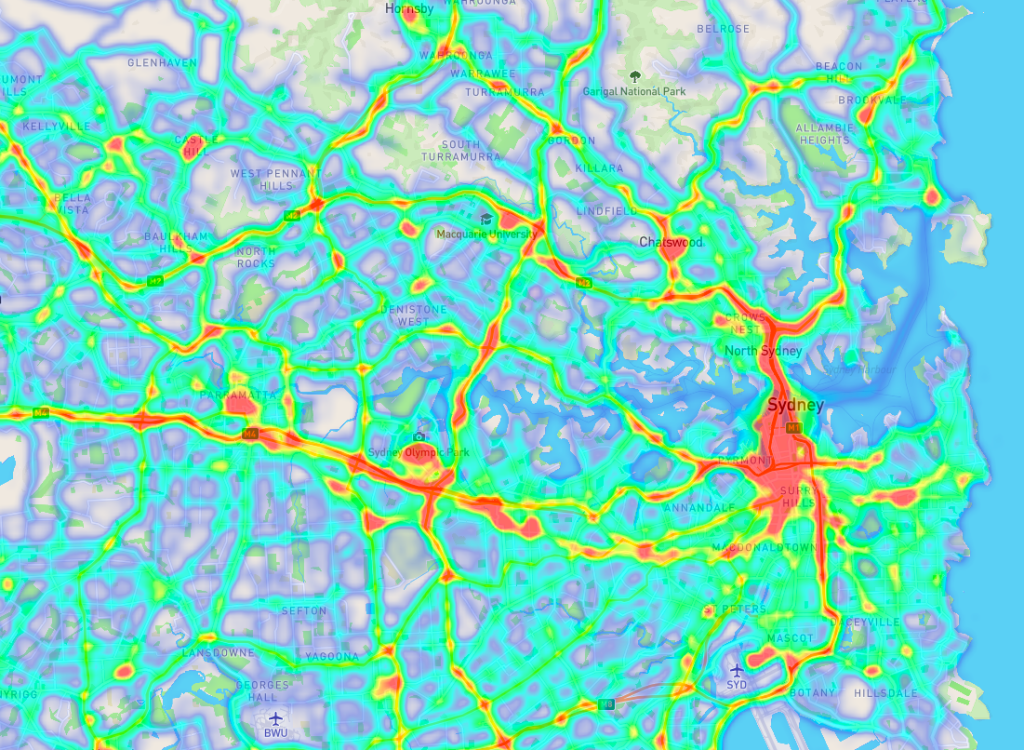

There are several types of Big Data that can be captured, correlated, and analyzed to provide supply chain managers with accurate insight to understand exactly where merchandise is at any given time and identify what might affect its programming.

Also read: “Benefits of supply chains mapping with Big Data“.

Here are a few examples of the ways in which organizations treat and receive location data:

- GPS-enabled devices: These devices are attached to vehicles, storage containers, or goods and allow constant updating of their location.

- Geofencing: Essential location intelligence technology to create a virtual geographic boundary.

- Direct integration with the technological systems of various physical locations: port, air, or ground operating systems.

The collection of this data and location intelligence techniques creates effective logistics optimization and route planning, allowing you to know exactly how and where items will move and to identify any bottlenecks affecting the delivery and collection processes.

Also read: “Can data science mitigate the supply chain crisis impact?“

These are some of the questions that location intelligence helps to answer in order to identify the delay in the supply chain and find the root cause of the problem.

- Where does it occur?

- Which organizations are involved?

- Which types of goods are affected?

- What events occur at specific times, dates, or seasons?

- What indicators are there that can show what the problem is?

Leveraging the right technology partner can solve many of these supply chain challenges, data gaps, and inefficiencies. Today’s supply chains and their stakeholders can benefit from applying these technologies to bring automation and predictive intelligence to their operations. Location intelligence is a key piece of this puzzle.

At PREDIK Data-Driven we generate solutions based on Big Data to help our customers solve delivery and collection problems in the distribution and last-mile processes.