Supply chain mapping brings companies strong and trusted relationships with suppliers, leading to better business results.

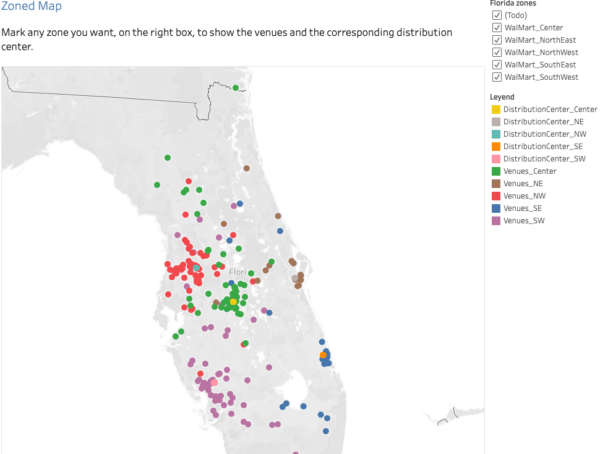

The ability to use Big Data in supply chain mapping allows businesses to automatically perform supply chain assessments, storing supplier information throughout the process to reduce operation fatigue in the future. By combining it with location analytics, you can supplement supplier data in an easily digestible and sharable format.

Also Read: Supply Chain Mapping – Case Study: Discovering tiers & relations in the US Food”

These are the steps to follow for supply chain mapping:

- Identify stakeholders

Collect data and identify all processes that contribute to the production, storage and distribution of products.

- Understand supplier relationships

Understand the relationships between all parts of the supply chain by identifying your first, second and third tier suppliers through a location analysis, identifying visits to different distribution centers, hidden tiers, detailing what is sold, to whom, and what is purchased.

This will allow you and your suppliers to get a better view of the potential risks, bottlenecks and pitfalls of relying on single suppliers and companies with long lead times.

- Establish costs and lead times

Calculate costs and lead times for each part of the chain, identifying the average time for each element and operation within the chain.

- Recognize risks

Recognize the risks associated with each entity, including political, legal, economic and environmental threats using real-time geospatial data.

- Track data

Track the flow of information and data through the chain, efficiently analyzing data, including orders, shipments and returns, can be as important to controlling costs as the movement of goods.

By collecting the additional information suggested above, you can more easily identify long lead times, inflation and unsustainable practices, saving valuable time and resources and streamlining your purchasing processes.

- Draw the current value stream map

This is the stage where you will need to identify all the activities required in the transaction.

- Draw the future value stream map and implementation plan

After discovering the area where there can be an improvement in the processes. Therefore, you will need to prioritize each area based on the ease of implementation as well as the potential benefits it can bring.

- Execute the implementation plan

At this stage, you will start executing the plan you outlined in the previous stage. You should start with the most value-added changes. Make sure that all changes are tracked in terms of cost and improvement.

- Repeat the process

Repeat the process and optimize times to obtain continuous improvement.

At PREDIK Data-Driven we help businesses implement strategies based on Big Data to improve supply chains, solve current problems, develop future strategies and generate optimal solutions, adding a location analytics model that will drive your business to the next level.