Unlike historical analytics, predictive supply chain analytics allows you to anticipate and prepare for the future, taking out the conjectures planning processes and improving decision making.

Predictive supply chain analytics use advanced technological tools such as machine learning, geomarketing, data mining that enables organizations to identify hidden patterns, understand market trends, identify demand, establish pricing strategies, achieve a high return on investment, optimize and reduce inventory costs.

You may also be interested in “Walmart Vs. Soriana: Who wins at the point of sale?“

Predictive analytics let supply chain professionals to improve several aspects, such as:

- Shipping and logistics.

Determine the optimal shipping frequency and quantities to satisfy the market demand and minimize costs, it’s also possible to determine strategic routes, taking account of the traffic congestion, distance, weather and delivery points.

- Demand forecasting

Enables improved demand forecasting by analyzing past and current trends and combining it with market intelligence and economic forecasts, forecast businesses demand.

[button button_text=”Like what you see? Request a free DEMO” button_style=”style-1″ button_arrow=”true” button_rounded=”true” font=”Default” button_size=”medium” font_size=”” button_icon=”” button_align=”center” padding_v=”” padding_h=”” button_link=”/request_demo/” link_open=”_self” href_title=”” id=”” class=”” bg_color=”” text_color=”” border_size=”” border_color=”” border_radius=”” h_bg_color=”” h_text_color=”” h_border_size=”” h_border_color=”” h_border_radius=”” margin_top=”” margin_bottom=”” margin_left=”” margin_right=””]

- Inventory management

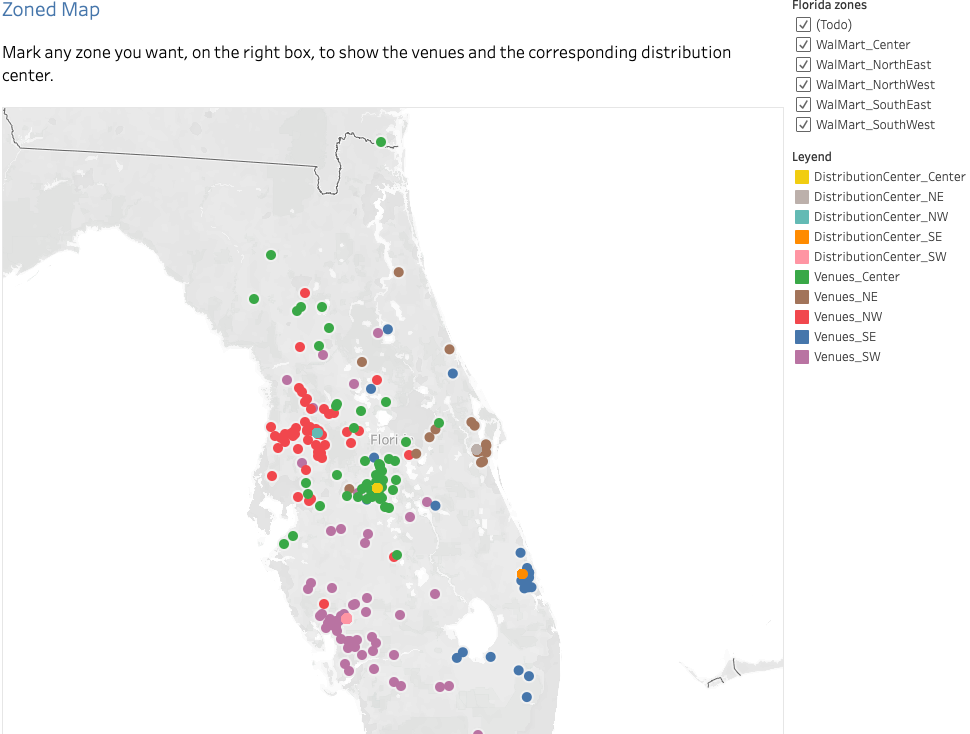

Predictive analytics determines the optimal inventory levels to minimize inventory, allowing supply chain managers to determine detailed inventory requirements by region, location and usage, reducing safety stock levels and placing inventory where it’s needed.

Also read: “POI Analysis and Characterization.”

- Maintenance

Predictive monitoring of equipment can identify when maintenance is needed, as well as provide advance warning of component failures, reducing spare parts inventories and avoiding unplanned equipment outages.

At PREDIK Data-Driven we help companies implement analytics to improve efficiency within supply chain processes.

Do you need an analysis to improve your efficiency in your supply chain processes?¡Contact us!