Predictive maintenance based on big data and geospatial data seeks to define the best time to perform work on an asset, so that maintenance frequency is as low as possible and reliability is as high as possible without unnecessary costs.

Maintenance teams are beginning to embrace the use of big data and predictive modeling to improve performance, which helps establish maintenance programs that reduce downtime and save maintenance costs, while extending the life of their equipment, reducing unnecessary tasks and optimizing spare parts inventory.

You might be interested in: “Predictive modeling for site selection strategies“

What is predictive maintenance?

Predictive maintenance is a technique that uses data analysis tools and techniques to detect anomalies in your operation and possible defects in equipment and processes, so that you can fix them before they cause a failure, this allows the frequency of maintenance to be as low as possible, without incurring the costs associated with doing too much preventive maintenance.

Using geospatial data is key to implementing a successful predictive maintenance program, as is the use of sensors and predictive maintenance techniques.

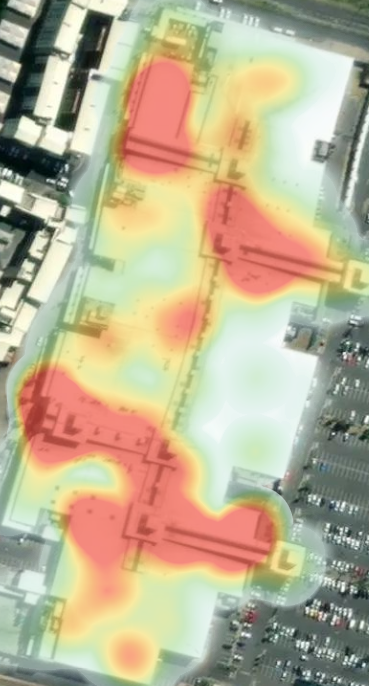

These tools capture information through sensors, industrial controls and enterprise systems, accurately identifying areas that need attention. Examples of the use of predictive maintenance sensors include vibration analysis, oil analysis, thermal imaging and equipment observation.

How does predictive maintenance work?

Predictive maintenance uses real-time and historical data from various parts of your operation to anticipate problems before they occur through:

- Real-time monitoring of asset condition and performance.

- Analyzing work order data.

- Benchmarking the use of MRO inventory.

Real-time machine data is used to accurately predict when a breakdown may occur. Data is collected through sensors (temperature, vibration, pressure, etc.) and fed into a machine learning model, helping maintenance personnel to monitor machine status and respond to problems in real time before they become catastrophic failures.

Also read: “Predictive models for the manufacturing industry“

Benefits of predictive maintenance

When predictive maintenance works effectively as a maintenance strategy, it is only performed on machines when it is necessary. That is, just before a failure occurs. This results in several cost savings by:

- Minimizing the cost of spare parts and supplies.

- Increasing the impact on that of traditional preventive maintenance, while laying the foundation for an analytics-driven maintenance services strategy.

- Minimize equipment maintenance time.

- Develop a true understanding of potential service interventions and a model that is effective in generating real value.

- Minimize production hours lost to maintenance.

- The role of big data is growing in maintenance, and this trend is improving the way maintenance managers optimize their strategies.

At PREDIK Data-Driven we support companies by implementing predictive models to optimize their processes, increasing the efficiency of their equipment and improving the performance of their machines.