Supply chain predictive analytics help companies to optimize their supply chain workflow by providing forecasts, identifying inefficiencies and driving forward innovation.

Data is helping supply chain management to accomplish things that were practically impossible years ago. In this scenario, predictive analytics has become the perfect way for companies to fight the complexity and the constant shifts that come with supply chain planning.

The constant crisis has taught decision-makers that not evolving evolve their response fast and efficiently, traduces in delays, missed obligations, and even shutdowns that end up in one result: Losing money (Lots of money).

According to expert sources like the WEForum, Mckinsey, and KPMG, some of the main challenges will be facing the supply chain will be:

Material access issues: Organizations may experience limited access to critical manufacturing inputs or spare parts and critical maintenance items. Key commodity prices and availability may fluctuate, disrupting the supply chain. Building resilient supply chains to combat future disruptions and adapt to new changes quickly is crucial.

Changing manufacturing footprint: Global corporations with manufacturing operations will re-evaluate their manufacturing footprint due to challenges accessing necessary materials and rising energy costs. Friendshoring and nearshoring will be considered, and there may be deeper thinking around whether manufacturing needs to be – and can be – done entirely onshore.

The labor market squeeze: Supply chains are under pressure from an ongoing labor market squeeze. The specific impacts of this squeeze are not explained in the available content.

These are the topics we will cover in our article:

Understanding Predictive Analytics

Most companies have a misconception about predictive analytics. While “predictive” might imply that it can predict future events, this type of analytics focuses more on estimating future outcomes based on historical, current, and alternative data.

Currently, no solution can predict the future; nevertheless, predictive supply chain helps identify new business opportunities and threats with the help of Big Data and Machine Learning solutions.

We recommend you reading our complete Guide about Predictive Analytics

The Role of Predictive Analytics in the Supply Chain

Data-driven operations are becoming the norm across industries, and Supply Chain Management is no exception. More and more SCM teams understand the advantages of predictive analytics and the value of using data from different sources (Including sales records, invoices, and delivery notes, to extract valuable, actionable insights).

It is important to state that most companies are currently in a “descriptive analytics phase.” That means they collect data to analyze past and current events. However, this “backward-looking” nature doesn’t offer insights into future trends.

That is why supply chain predictive analytics is the next logical step for most SCM teams. Over recent years, predictive analytics has evolved alongside the supply chain landscape. Its accessibility and affordability have increased, encouraging businesses of all sizes to implement this technology.

In our experience, large brands are particularly aware of the value of predictive analytics for making a crucial inventory, production, and operative decisions. However, this comprehensive analytics encompasses the entire supply chain flow – from procurement to the end customer.

For example, when coupled with Big Data methodologies, predictive analytics can significantly enhance the supply chains of manufacturing companies, facilitating their navigation through the complexities of Industry 4.0.

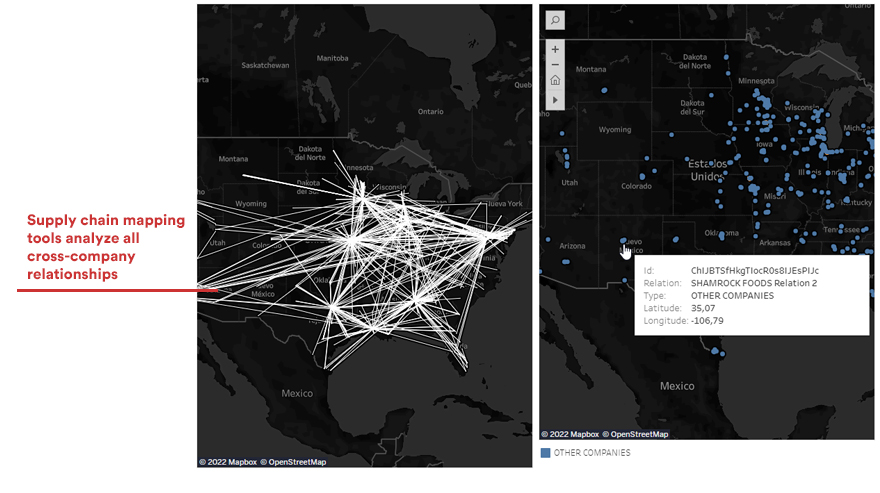

Are you looking for Smart Analytics for your SCM? Learn more about our Supply Chain Mapping Tools

Benefits of using Predictive Analytics for Supply Chain Visibility

Incorporating predictive insights across logistics, purchasing, warehousing, and inventory control can lead to numerous benefits.

These include cost reductions, enhanced operational efficiency, improved customer engagement, and the prevention of supply chain disruptions.

Supply chain visibility provides an overview of the involvement of suppliers, logistics partners, and customers in the supply chain. It enables monitoring of supply and distribution systems, allowing for identifying and resolving disruptions before they escalate. Furthermore, it helps track important metrics such as product volume, quality, and delivery time, providing a real-time view of every stage of the supply process.

Forecasting Demand

Predictive analytics are vital in preparing businesses for future demand. The key here is to act proactively. For example, companies can strategize based on forecasts rather than responding to increased sales afterward. This prevents missed opportunities and unhappy customers.

The “specialty” of predictive insights is forecasting. Applying the correct model can generate insights into future sales volumes, market demand, and seasonal fluctuations.

For instance, predictive analytics can indicate a possible spike in demand for a product in a specific region. With this in mind, companies can have time to plan a new strategy to ensure additional unit availability. This approach improves customer satisfaction and optimizes revenue opportunities.

Production Planning

Predictive modeling brings many benefits when organizing and planning production. With data like past sales and demand forecasts, predictive supply chain analytics can offer demand planning, forecasting, and optimization solutions.

By combining the results given by these models with other data, such as costs and capacities, businesses can work out exactly how much inventory they need for each product. This inventory analysis can contemplate different times and situations throughout the year.

Predictive analytics also deals with possible unexpected issues within supply chain management. For example, what happens if a big customer decides not to place an order? Or if a supplier fails to meet their obligations?

Well, predictive solutions can consider situations like these before they happen. This can prepare businesses to avoid overstock and understock issues.

Also, predictive models can help businesses schedule production in the best way possible, considering the different stages of the process and the demand for each product. This can lead to better use of resources and cost-effective decisions regarding the products that should be made.

Inventory Levels

Inventory management is another critical area where predictive analytics can make a big difference. As you know, having too much inventory can be expensive, but not having enough results in lost sales. Predictive models help businesses keep the right amount of supplies on hand, lowering costs and reducing waste.

Also, based on past customer behavior, SCM teams can use predictive analytics to determine how much inventory they need. Predictive models can also consider upcoming events such as holidays or end-of-season sales (These events tend to increase demand).

We recommend you reading: Big Data for Effective Supply Risk Assessment

Predictive Maintenance

One standout application is predictive maintenance. Predictive methods can assist in detecting potential operational disruptions before they occur and mitigate expensive breakdowns.

It’s also a key player in streamlining maintenance processes, delivering a competitive advantage to businesses. As a result, it strengthens productivity and reduces operational costs consistently.

A great example of predictive maintenance is the predictive monitoring of necessary equipment. By allowing for well-timed scheduling of repairs, it minimizes the risk of unexpected equipment failures preventing production delays or excessive wastage due to obsolete machinery components.

Route planning

Predictive data can significantly contribute to enhancing logistics and transportation operations. Supply chain managers can have better control over the quality, volume, and frequency related to transportation.

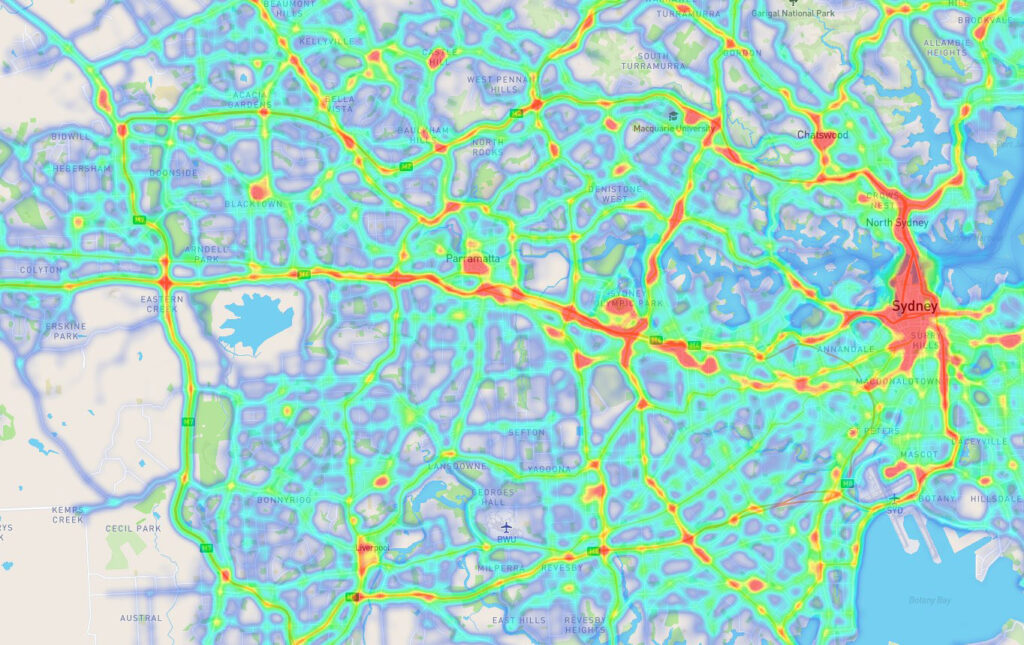

For example, when planning a route, predictive models can consider traffic conditions, distance between locations, weather conditions, and delivery performance to determine the most efficient routes. The benefits? Less fuel consumption per unit, delivery schedule optimization, and efficient processes.

We also recommend you read: The Importance of Location Analytics for Supply Chain Management

Why invest in Machine Learning and analytics-based solutions?

You gain greater visibility and 360-degree responsiveness by assessing performance on a broader scale, predicting and minimizing risks and negative impacts on distribution channels.

Improves customer experience by creating personalized products based on current user demands. A widely used example can be modern transportation and logistics using voice-activated means to track shipments and orders.

It increases fleet efficiency by enabling better navigation and route optimization for freight and transportation. These tools access the most effective route for product delivery by processing driver, vehicle and customer data through machine learning. Simultaneously, they help you save both time and money for future shipments.

Generates competitive advantage by leveraging real-time data from external resources such as industrial production, weather and employment history, helping to better gauge market conditions and assess upcoming demands for stable growth.

Enables access to future insights by determining customer needs before they require them.

Increases demand forecasting in warehouse supply and demand management, driving inventory optimization, where warehouse and inventory managers are informed about real-time control of parts, components and finished goods.

Increases transportation and logistics longevity from vehicle-generated data that provides real-time information on the longevity of transportation vehicles, making maintenance recommendations and failure predictions based on past data.

Improves the addition of portability to the supply chain loading process by gaining real-time, actionable visibility into the loading process. The data collected can also be used to design less risky and faster process protocols for handling packages.

Saves costs and increases revenue by pinpointing changes in the supply chain profit process and managing courier contracts to negotiate better shipping and provisioning rates.

Improves strategic sourcing based on data analytics in the supply chain, helping to standardize least-cost alternatives and predict supply performance indicators for compliance.

Final thoughts

Supply chain predictive analytics is one of the most effective methods for SCM managers and decision-makers. SC Analytics offers numerous benefits tailored to meet your business’s specific needs. By leveraging this technology, you can expect:

- Increased visibility

- Deeper insights

- Improved decision-making support

- Better resource planning

- Optimized supply chain operations.

By partnering with PREDIK Data-Driven, we can help you unlock the full potential of supply chain predictive analytics and navigate the complexities of implementation, ensuring sustainable and long-term success for your organization.